Jose Montero PhD, WellCAD Product Manager

Rien Corstanje, Geologist & Hydrogeologist, Sales & Support Engineer

Ida Hooshyari PhD, Training & Support Engineer

Mariano Rodriguez, Geologist, Sales & Support Engineer

Introduction

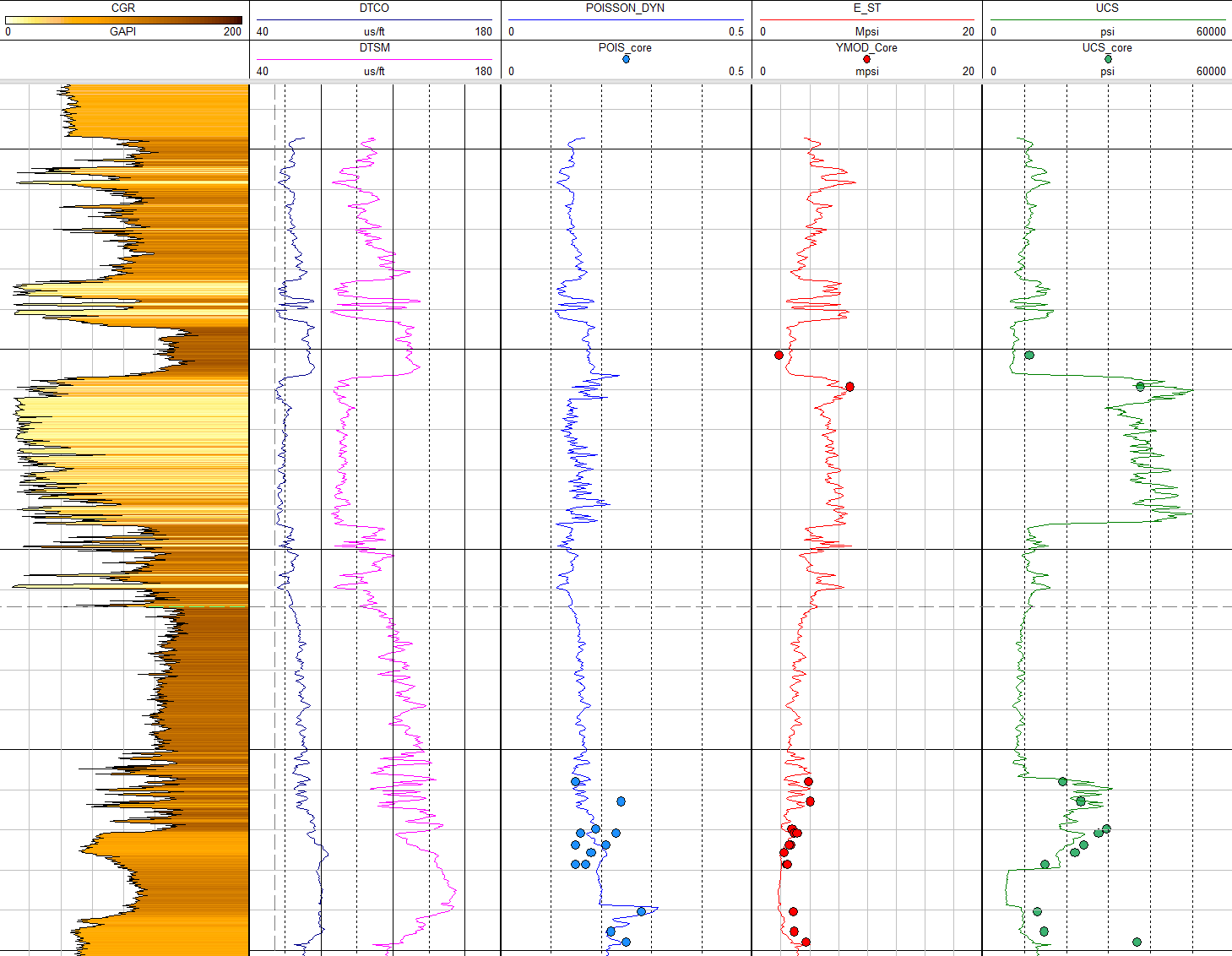

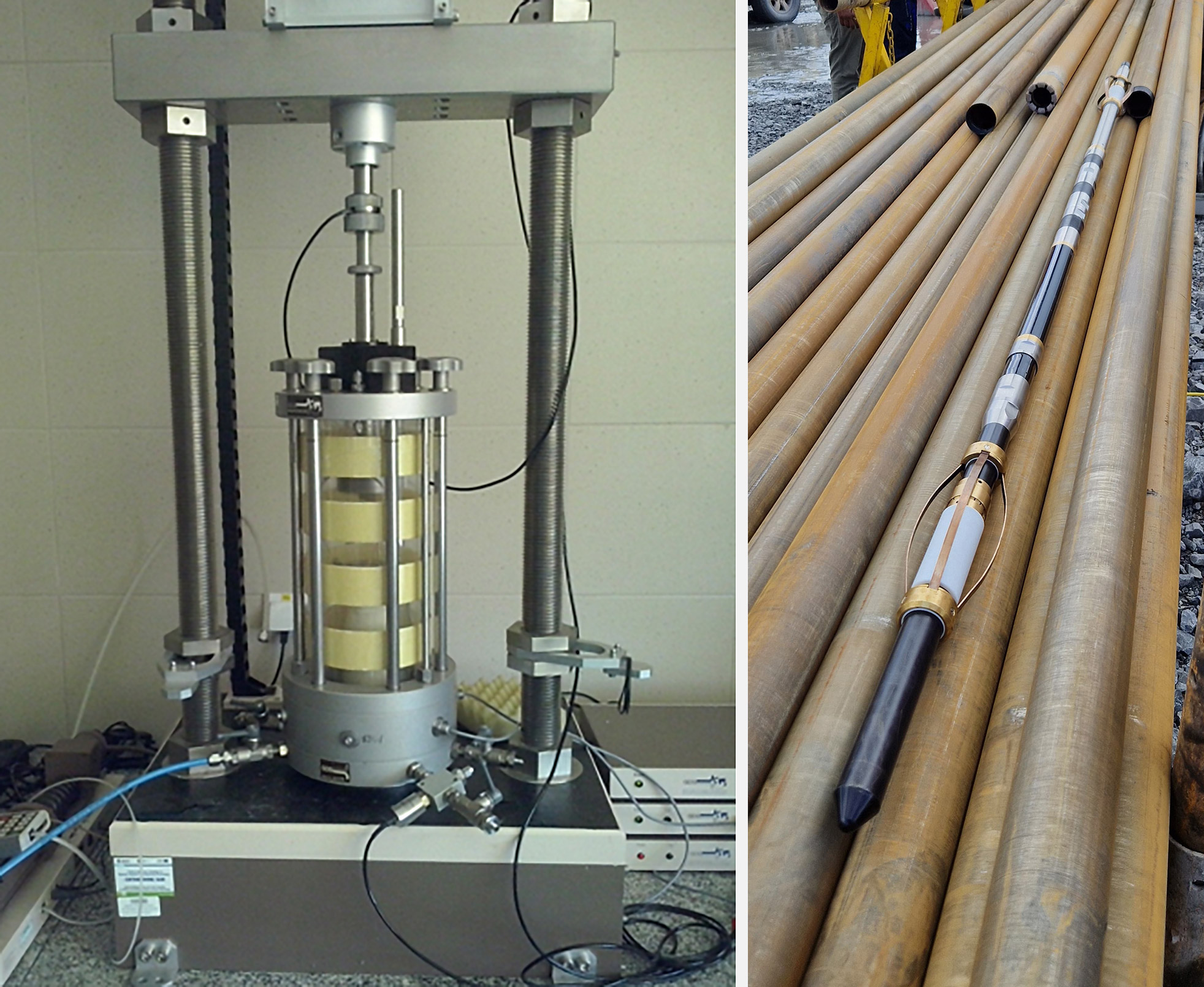

Core-to-log reconciliation is a critical step in geomechanical analysis because it enables the integration of laboratory-derived static rock mechanical properties with log-derived dynamic measurements. While laboratory testing on core plugs provides direct measurements of static properties such as Young’s modulus, Poisson’s ratio, and uniaxial compressive strength (UCS), these measurements are limited in spatial coverage and can be affected by coring-induced damage, stress relief, and scale effects.

In contrast, wireline or LWD Full wave sonic logs offer continuous in-situ dynamic measurements over the entire borehole interval by recording compressional (Vp) and shear (Vs) wave velocities. These velocities can be used to calculate dynamic elastic properties, but due to differences in stress state, strain rate, frequency, and scale, dynamic properties often differ significantly from their static counterparts.

Static vs Dynamic

In subsurface geomechanical analysis, understanding and accurately characterising the mechanical behaviour of formation and overburden rocks is critical for applications such as wellbore stability modelling, fault stability and slip tendency analysis (pit slope stability), thermal stress analysis in enhanced geothermal systems (EGS), caving a subsidence prediction, etc. Two primary sources of mechanical property data are:

- Static measurements: obtained from laboratory testing of core plugs (e.g., triaxial compression, unconfined compressive strength tests).

- Dynamic measurements: derived from Full wave sonic well logs (e.g., compressional and shear FWS logs).

Each of these data sources provides valuable but fundamentally different types of information due to their measurement scales, boundary conditions, and physical principles. Core-to-log reconciliation is the essential process of integrating these datasets to ensure consistency and reliability in geomechanical models.

Reconciliation of these datasets is therefore essential to:

- Calibrate dynamic logs using reliable static data, ensuring more accurate property prediction in uncored or untested intervals.

- Bridge the scale gap between core and log measurements, enhancing the reliability of geomechanical models.

- Support wellbore stability analysis, fracture gradient prediction, and reservoir geomechanics by providing more representative rock mechanical properties at the field scale.

- Quantify formation heterogeneity by understanding how elastic properties vary across different lithologies and facies.

Ultimately, core-to-log reconciliation improves the predictive power of geomechanical models used in well planning, hydraulic fracturing, reservoir stimulation, and field development decisions, especially in complex or unconventional reservoirs.

Why the Reconciliation is Necessary?

There are different reasons but the most important are 1) Loading conditions and strain rates, 2) Laboratory vs In-situ conditions and 3) Limited Core Coverage.

1. Loading conditions and strain rates

Static properties such as Young’s modulus, Poisson’s ratio and UCS are measured under low-frequency loading conditions (~0.01–1 Hz) and small strain rates, replicating field-relevant mechanical deformation. On the other hand, dynamic properties are computed from high-frequency (~10–20 kHz) acoustic wave velocities (Vp and Vs), assuming linear elastic behaviour. Due to these differences, dynamic moduli are typically higher than static moduli, often by 20–50% or more depending on lithology, porosity, and degree of cementation. Therefore, applying dynamic-derived values directly in geomechanical models can lead to overestimation of rock stiffness and strength, resulting in inaccurate predictions of mechanical behaviour under in-situ stress conditions.

2. Laboratory vs In-situ conditions

Core samples are often subject to stress relief, microcracking, desaturation, and other alterations during coring and handling, which can modify their mechanical response. Full wave sonic logs, on the other hand, are recorded in-situ, capturing the rock’s behaviour under reservoir pressure and saturation conditions. Without reconciliation, this disconnects between lab and field data introduces systematic errors in modelling mechanical responses such as elastic deformation, pore pressure changes, and fracture propagation.

3. Limited Core Coverage

Core acquisition is expensive and typically only covers selected intervals. Logs provide continuous vertical coverage, allowing for the extension of geomechanical property profiles into sections without core samples. However, this is only reliable if dynamic-to-static relationships are properly calibrated.

How are Core-to-log Reconciliation Techniques Implemented?

Core-to-log reconciliation provides a robust framework for integrating high-resolution laboratory measurements with continuous log data. The key objectives of this reconciliation process are:

- Derive Empirical or Rock Physics-Based Correlations Between Dynamic and Static Properties. Core-to-log reconciliation allows the derivation of empirical or semi-empirical relationships (e.g., linear regression, machine learning models, or rock physics transforms like Gassmann’s equation) that convert dynamic log data into field-representative static parameters. These relationships are essential for upscaling laboratory results and enabling predictive modelling in uncored intervals. However, due to frequency-dependent elastic behaviour, static and dynamic properties differ significantly, especially in heterogeneous or poorly consolidated rocks. An example of this might be a calibrated equation such as: Estatic=α⋅Edynamic+β that allows for a static Young’s modulus to be estimated from FWS logs, where α and β are regression coefficients derived from core-log matched data.

- Calibrate Log-Derived Mechanical Properties Against Lab Data. Dynamic moduli calculated from full wave sonic logs are inherently optimistic when applied directly in geomechanical models, especially for formations with fractures, weak cementation, or clay content. Through reconciliation, these log-derived properties are adjusted (or calibrated) using ground-truth data from core plug testing. This ensures that the elastic and strength parameters used in modelling reflect realistic field conditions, not just theoretical elastic behaviour. Calibration enables: i) adjustment of stiffness and strength values to avoid overestimation, ii) Improved wellbore stability predictions, as elastic properties directly affect the mechanical response under in-situ stresses and iii) consistent comparison across boreholes, where core availability is limited.

- Account for lithological variations. Different rock types respond differently to stress due to variations in grain size, mineralogy, porosity, fabric, and diagenetic history. For example, sandstones with quartz cementation have a different dynamic-static modulus ratio than shaly sands or carbonates often show nonlinear behaviour due to microfractures or stylolites. Core-to-log reconciliation allows geomechanists to segment the dataset into geologically or petrophysically meaningful domains, such as: lithofacies (e.g., clean sandstone, argillaceous sandstone, marl) porosity classes (e.g., tight vs. porous zones) or rock fabric types (e.g., laminated vs. massive). Separate calibration curves can then be derived for each domain, resulting in more accurate, zone-specific mechanical property profiles. Lithological variations can be of particular interest when a single global dynamic-to-static correlation across a heterogeneous formation may obscure important mechanical contrasts, leading to errors in stimulation design or stability assessments.

- Improve spatial extrapolation of geomechanical properties field-wide. Once core-to-log relationships are established and validated, they can be applied field-wide, allowing for the extrapolation of static mechanical properties into uncored borehole intervals, offset borehole or entire geocellular models. This extrapolation enhances the resolution and reliability of field-scale geomechanical models (e.g., Mechanical Earth Models), reduces uncertainty in unsampled areas, and enables geomechanical risk screening across development areas.

Practical Implications

Core-to-log reconciliation plays a strategic role in mining geotechnics by enabling the upscaling of reliable rock mechanical properties from limited laboratory data to field-wide geotechnical models. These reconciled datasets underpin critical engineering decisions throughout the mine life cycle, from pre-feasibility studies to closure. The following are key practical implications in various domains:

Wellbore stability predictions

During drilling, the wellbore is subjected to a complex interplay of in-situ stresses, pore pressures, and induced mechanical stresses. Accurate prediction of wellbore stability whether against collapse (shear failure) or fracturing (tensile failure) depends on knowing the elastic and strength properties of the surrounding formation. Dynamic elastic moduli derived from FWS logs tend to overestimate stiffness due to frequency effects. If these uncorrected values are used in wellbore stability models (e.g., Mohr-Coulomb, Mogi-Coulomb), they may suggest a falsely high resistance to deformation.

By reconciling with static core data, the model can:

- Accurately predict critical mud weight windows (safe drilling margins).

- Avoid underestimating borehole collapse risk in weak or ductile zones.

- Prevent unintentional fracturing in depleted or overpressure intervals.

- Improve planning for directional drilling in stress-sensitive formations.

Improved Rock Mass Characterization for Design Optimization

By calibrating log-derived data with static mechanical properties, engineers can generate more realistic and continuous profiles of UCS, Young’s modulus, Poisson’s ratio, cohesion, and friction angle across the mine. These properties are essential inputs for:

- Open-pit slope design

- Underground excavation stability

- Support system selection

- Numerical modelling of rock mass behaviour

Without reconciliation, the mechanical contrast between lithological units may be misrepresented, leading to over-conservative designs (increased costs) or underestimated hazards (increased risk).

Better Stope and Pillar Design in Underground Mining

In room-and-pillar or cut-and-fill operations, designing stable stopes and pillars depends on knowing the actual strength-to-stress ratio of the rock mass. Reconciled static properties allow engineers to:

- Determine realistic yield points for different lithologies.

- Adjust pillar dimensions based on rock strength variability.

- Account for anisotropy and heterogeneity in weak or fractured zones.

- This leads to safer extraction strategies and improved ore recovery without compromising structural stability.

Fracture Stimulation Design

In hydraulic fracturing, the ability to initiate and propagate fractures depends on the elastic response and strength limits of the target rock. Parameters like Young’s modulus, Poisson’s ratio, tensile strength, UCS, and fracture toughness directly influence the fracture geometry and growth direction, breakdown pressure, net pressure and proppant transport and the stimulated reservoir volume (SRV). If uncorrected dynamic moduli are used in stimulation models, the rock may appear stiffer and more brittle than it actually is, leading to:

- Overestimation of fracture height and length

- Underdesign of pumping schedules or proppant volumes

- Misjudgement of fracture containment potential in layered formations

Mechanical Earth Model Development

A Mechanical Earth Model is a foundational tool for geomechanical analysis. It integrates data on rock properties, in-situ stresses, and pore pressure to predict deformation behaviour, stress changes, and mechanical risks over time. MEMs require consistent, calibrated input data particularly elastic moduli, strength parameters, and density profiles across vertical and lateral extents. Relying solely on dynamic logs introduces systematic bias into stress and strain calculations. Reconciled data enables:

- Depth-consistent elastic and plastic property models

- More accurate stress path modeling (e.g., for depletion or injection scenarios)

- Better input for forward simulations (e.g., subsidence, compaction, casing deformation)

- Enhanced reliability in 4D geomechanics workflows

Field-wide Geomechanical Risk Assessment

Understanding mechanical risks across an entire field is essential for reservoir management, infrastructure planning, and safety assurance. Some examples are: fault reactivation processes (which can lead to seismic events or unintended fluid migration), caprock failure (threatening seal integrity in CO₂ storage or hydrocarbon traps) or reservoir compaction (which may damage wells, facilities, or overlying strata). Static mechanical properties calibrated across logs allow for field-scale mapping of:

- Brittle/ductile transition zones

- Stress concentrations near faults or fractures

- Depletion-sensitive zones likely to compact or deform

- Seal integrity maps based on realistic strength/stiffness contrasts

These reconciled inputs can be used in coupled geomechanical models (e.g., reservoir simulators + geomechanics modules like Abaqus, CMG-GEM + FLAC3D) to predict responses under various operating scenarios.

How WellCAD can help to core-to-log reconciliation processes

The Geomechanics workspace in WellCAD has been purpose-built to support common workflows encountered in the analysis of geomechanical data. Among its key features is full support for core-to-log reconciliation, enabling users to integrate laboratory-derived static rock mechanical properties with dynamic log-based measurements.

WellCAD provides a comprehensive toolkit for calculating essential rock mechanics parameters such as Young’s modulus, Poisson’s ratio, and unconfined compressive strength (UCS). These calculations can be applied either across the entire length of the borehole or restricted to specific zones of interest, allowing for detailed, targeted analysis.

Users can easily define intervals where both static (core) and dynamic (log) data are available and perform reconciliation through an interactive trial-and-error approach. The platform offers predefined calculation workflows, organized by lithology type, to help guide users through the reconciliation process. These predefined methods are selected based on their proven relevance in both academic research and industry practice, ensuring users have access to scientifically robust and field-tested techniques.

With its user-friendly interface and geomechanics-specific capabilities, WellCAD enables geoscientists and engineers to perform accurate, zoned calibrations and build more reliable geomechanical models for applications in drilling, mining, and reservoir engineering.

At ALT, we recognize that the default lithology processing workflows provided in WellCAD may not always deliver the level of accuracy required for every dataset or geological context. To address this, we developed the Custom Equation Editor, a powerful feature embedded within the Geomechanics module, designed to provide users with full flexibility and control over their analytical methods.

This functionality allows users to implement user-defined equations or processes tailored to various types of workflows including the core-to-log reconciliation process. Whether derived from in-house research, spreadsheet models, or peer-reviewed publications, custom equations can be quickly imported either through simple copy-paste operations and applied directly within WellCAD.

Once created, custom processes can be:

- Saved within the project for repeated use,

- Organized and managed via the editor interface, and

- Shared with colleagues for consistent geomechanical evaluation across teams or projects.

By leveraging the Custom Equation Editor, users are no longer limited to preconfigured workflows. Instead, they gain the flexibility to adapt industry or academic methodologies, optimize reconciliation for complex lithologies, and apply site-specific calibration techniques, all while maintaining WellCAD’s ease of use and integration capabilities.

If you have questions, feedback, or suggestions, feel free to contact us at ALT Support: support@alt.lu

We are always here to help and continuously improve your WellCAD experience.