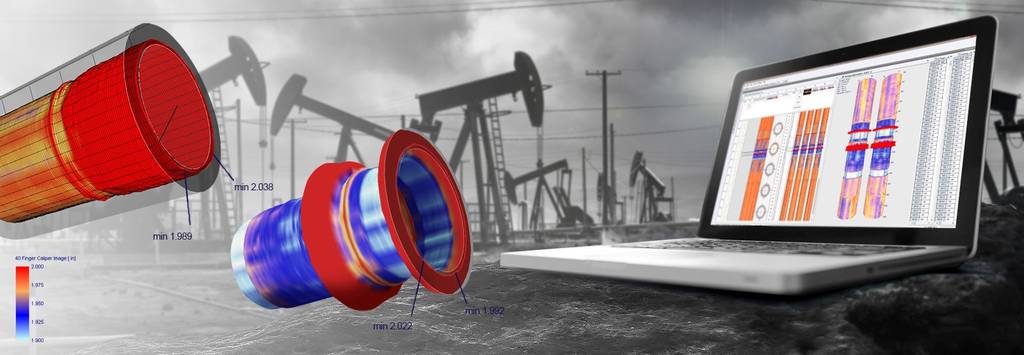

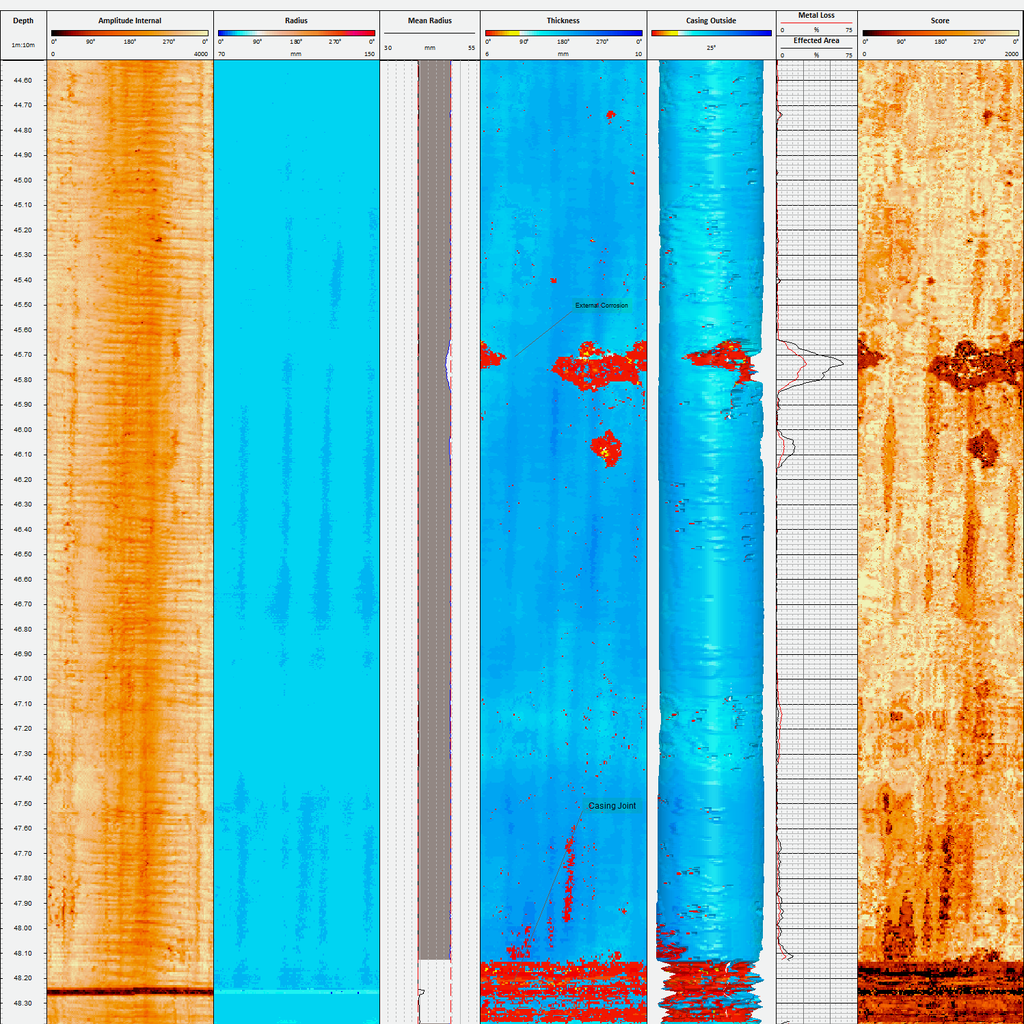

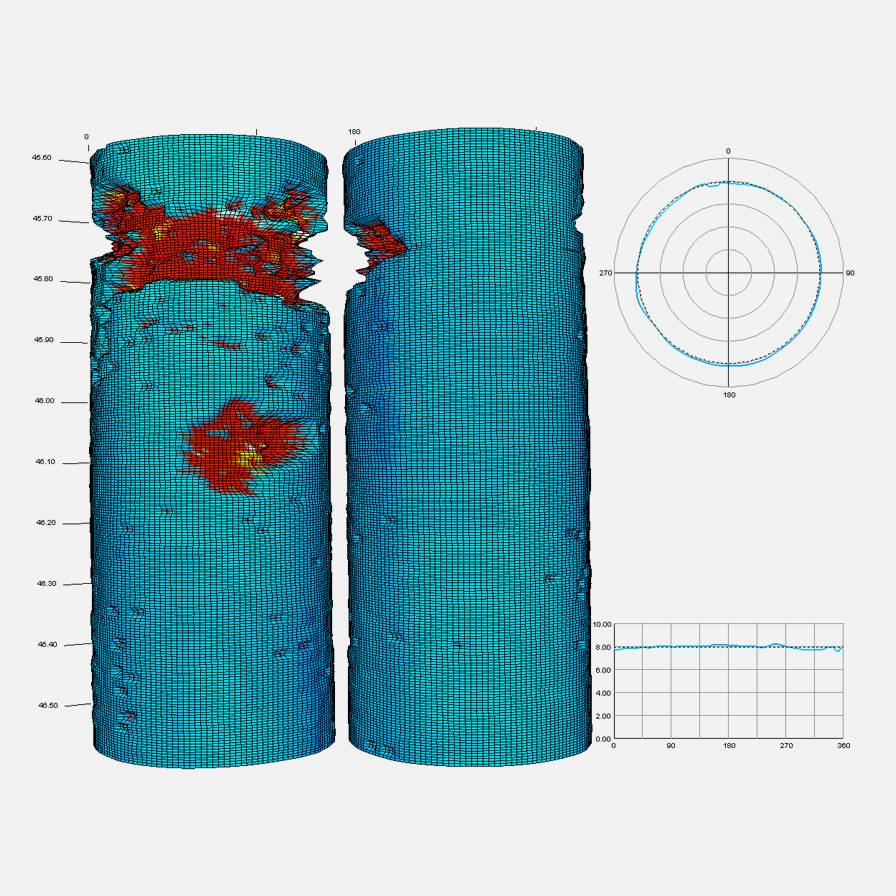

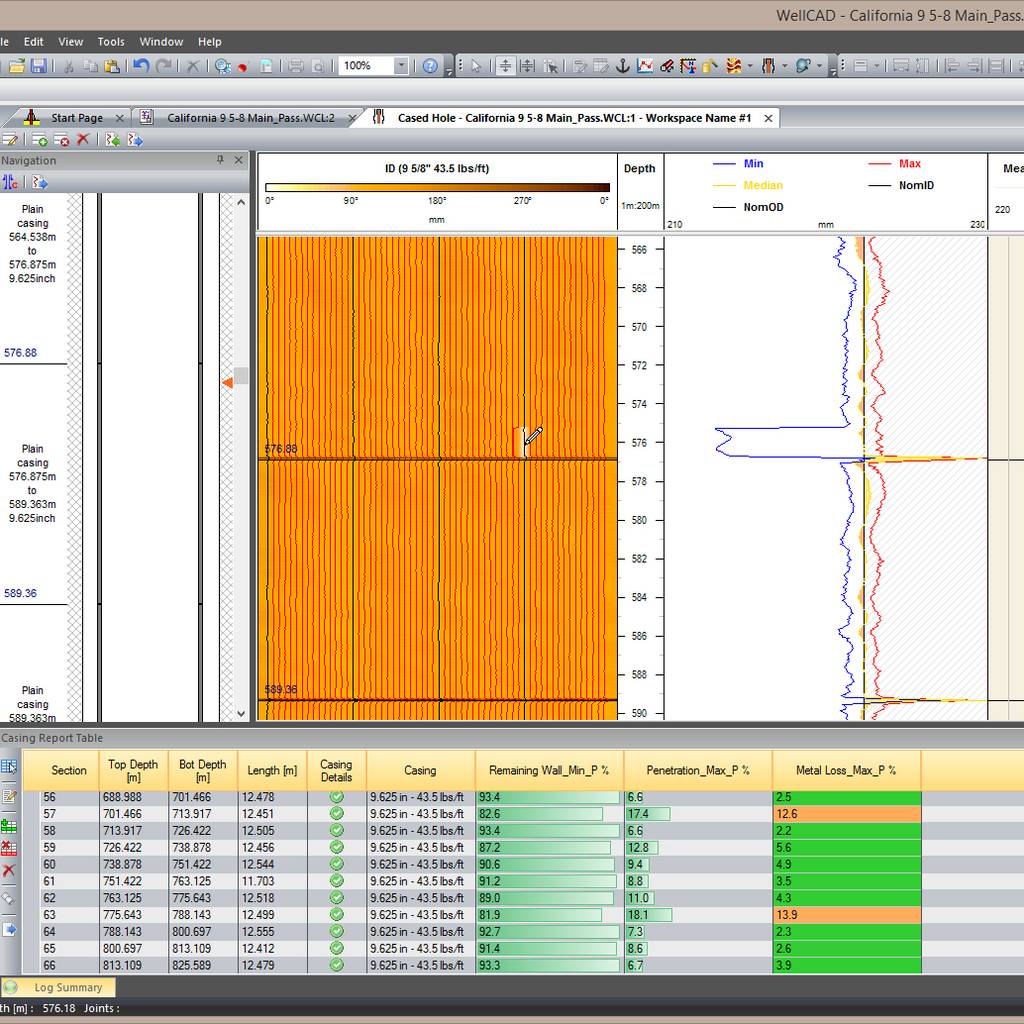

The Casing Integrity module offers processing algorithms dedicated to multi-finger caliper and ultrasonic televiewer data. A made-for-purpose workspace is used to analyze pipe sections and provides comprehensive data presentation tools.

- Log editing, unit conversion, depth matching, splicing, and merging.

- Correction for drift, dead sensor, decentralization, conditional corrections, and more.

- Fluid velocity estimation, travel time to radius/diameter and travel time to thickness conversion.

- Automatic pipe detection and interactive joint editing.

- Computation of more than 35 different statistical parameters derived per pipe section or per sample point.

- Full graphical and tabulated result feedback.

- Seamless integration into WellCAD borehole documents to provide comprehensive analysis reports (e.g., to combine open hole and cased hole data).

- Binary, ASCII and graphics export (WCL, LIS, DLIS, LAS, CSV, XLS(X), JPG, PNG, TIF, PDF).

- 3D data viewer.

CLOSE

1 of 20